kodde

New member

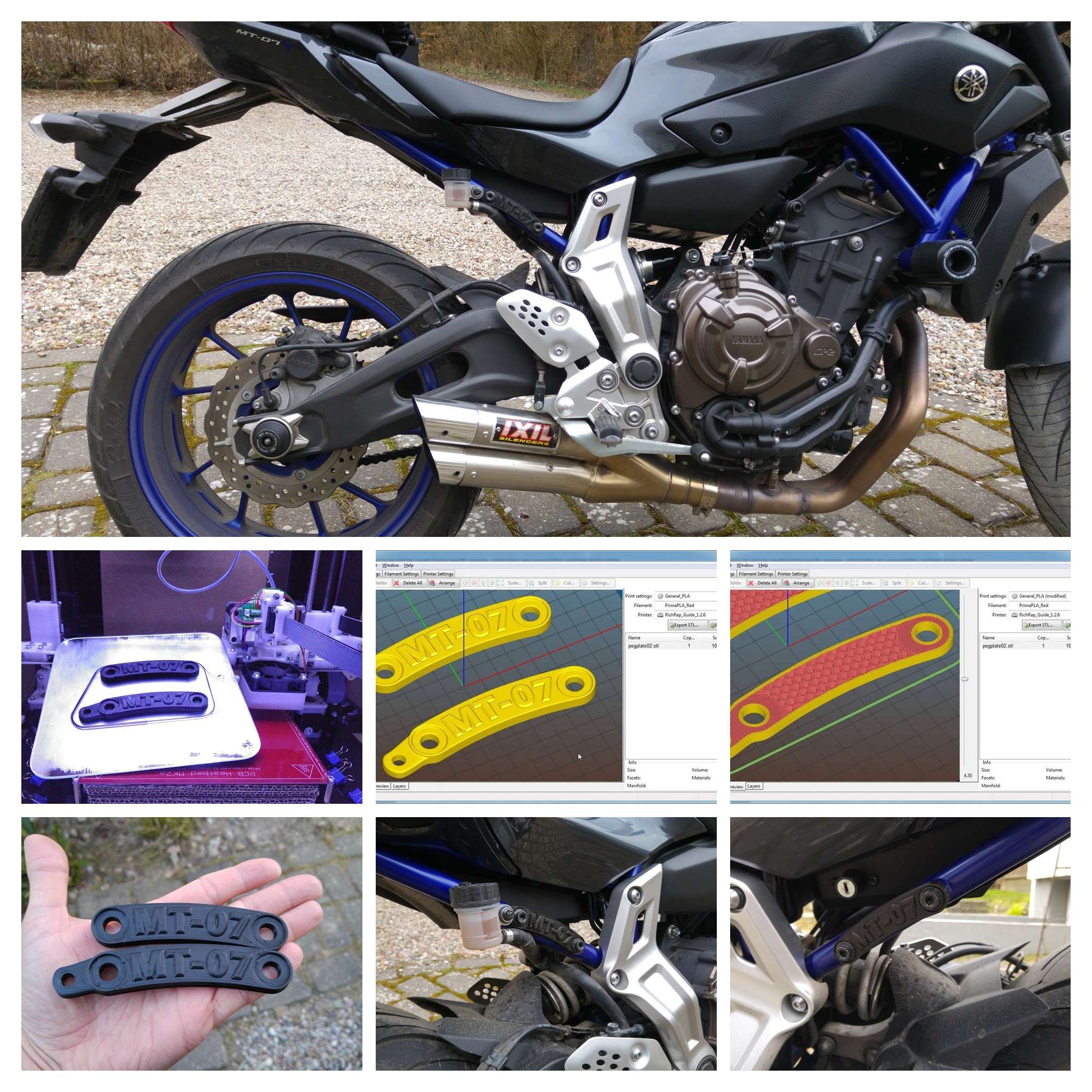

Hey guys.

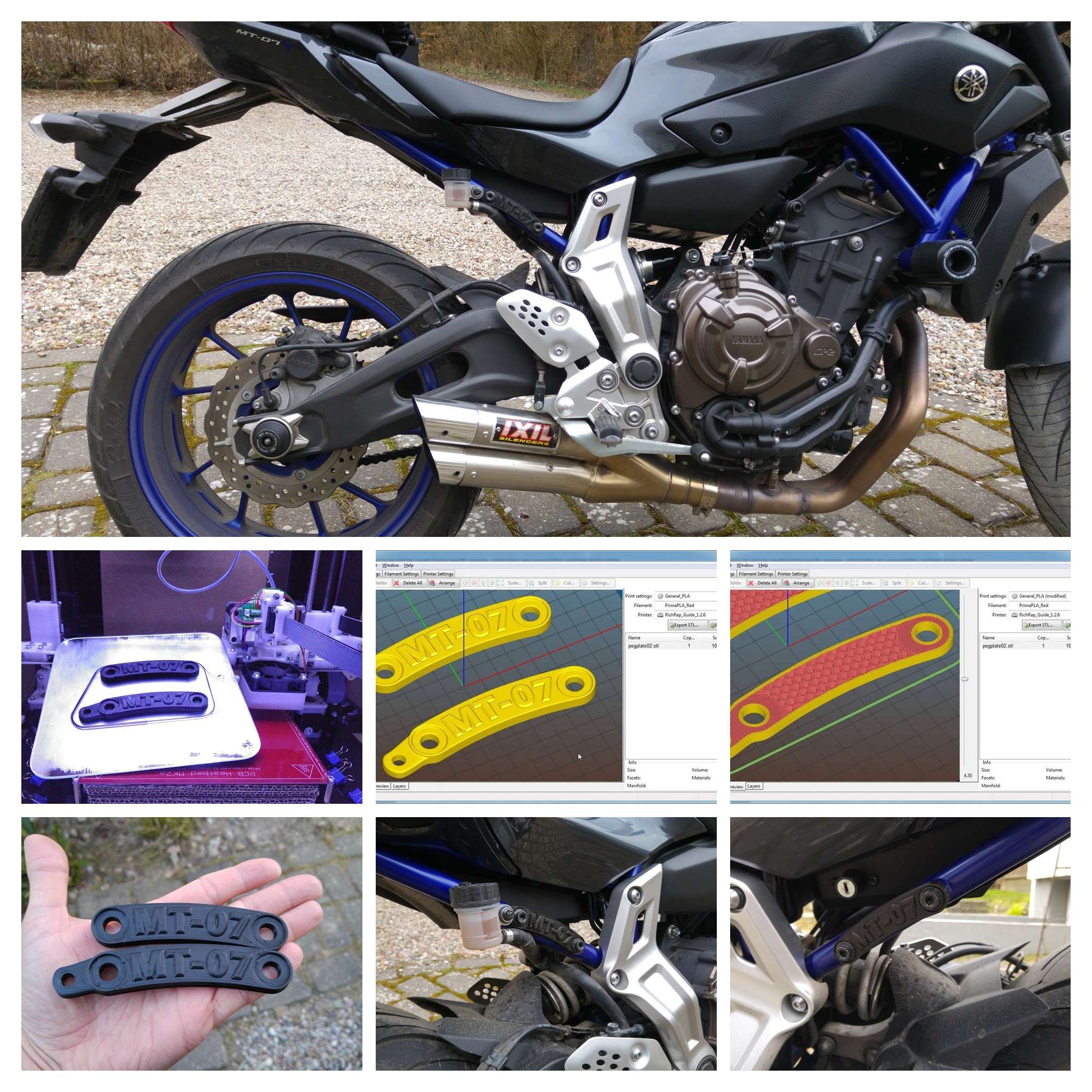

Was contemplating on buying the evotech passenger footpeg blanking plates but I though £40 for such a small metal part was too much.

Decided to design and print my own parts from PLA plastic. What do you think?

Was contemplating on buying the evotech passenger footpeg blanking plates but I though £40 for such a small metal part was too much.

Decided to design and print my own parts from PLA plastic. What do you think?